aluminum 6061 cnc machining The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability makes it a versatile alloy. uxcell 7.9"x4.7"x2.2"(200mmx120mmx56mm) ABS Junction Box Universal Project Enclosure W PC Transparent Cover light Gray Visit the uxcell Store 4.5 4.5 .

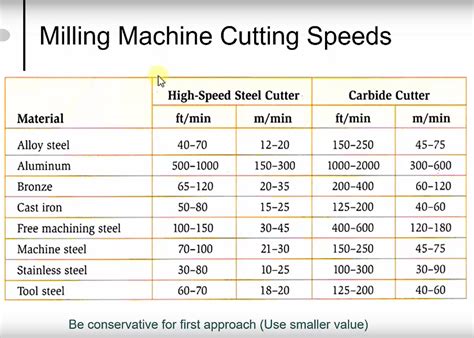

0 · surface speed for 6061 aluminum

1 · sfm range for 6061 aluminum

2 · recommended cutting speed for aluminum

3 · cutting speed for 6061 aluminum

4 · casting 6061 aluminum

5 · aluminum machinability chart

6 · aluminum alloy machinability chart

7 · 6061 aluminum machinability chart

60 AMP UTILITY DISTRIBUTION BOX (UDB) SERIES. Safe, weatherproof, man-portable method to distribute power to branch circuits, utility extension cords and lighting fixtures in military or .

Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition

The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability .Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability makes it a versatile alloy.

In this CNC materials video, we show and discuss several parts that were CNC machined using aluminum 6061. We'll also explain the properties of the CNC machi.

6061-T6 aluminum is lightweight, has high corrosion resistance, excellence strength and machining are easy. The disadvantages of aluminum are that it is costly and less strong than steel. Knowing these pros and cons helps in . With its high strength and corrosion resistance, CNC machining 6061 aluminum products extensively used in industrial structural and more fields. Starting with the 6061 aluminum properties, we’ll find out its difference between aluminum 6063 and 7075, as well as prices. Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can achieve exceptional results. In this article, we will explore 6061 aluminum machinability and provide tips and techniques to help you optimize your machining process.

6061(T6) aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process.6061 aluminum material belongs to heat-treatable strengthening alloys, with good formability, weldability, and machinability.6061-T6 aluminum is a popular choice for CNC machining due to its excellent properties. This grade of aluminum offers good corrosion resistance, making it ideal for use in harsh environments. In addition, its weldability makes it suitable for joining multiple parts together.

6061-T6 Aluminum. 6061-T6 aluminum is precipitation-hardened 6061 aluminum. 6061 aluminum is one of the most versatile, common aluminum alloys that may be heat treated. The main alloying elements for 6061 aluminum are silicon and magnesium.

6061-T6 is one of the most popular aluminum alloys on the market and most manufacturing companies offer it as the standard grade for CNC machining. It’s versatile, easy to machine, and 6061 can even have different heat treatments.Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability makes it a versatile alloy.In this CNC materials video, we show and discuss several parts that were CNC machined using aluminum 6061. We'll also explain the properties of the CNC machi.

6061-T6 aluminum is lightweight, has high corrosion resistance, excellence strength and machining are easy. The disadvantages of aluminum are that it is costly and less strong than steel. Knowing these pros and cons helps in .

surface speed for 6061 aluminum

With its high strength and corrosion resistance, CNC machining 6061 aluminum products extensively used in industrial structural and more fields. Starting with the 6061 aluminum properties, we’ll find out its difference between aluminum 6063 and 7075, as well as prices.

Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can achieve exceptional results. In this article, we will explore 6061 aluminum machinability and provide tips and techniques to help you optimize your machining process. 6061(T6) aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process.6061 aluminum material belongs to heat-treatable strengthening alloys, with good formability, weldability, and machinability.6061-T6 aluminum is a popular choice for CNC machining due to its excellent properties. This grade of aluminum offers good corrosion resistance, making it ideal for use in harsh environments. In addition, its weldability makes it suitable for joining multiple parts together.

6061-T6 Aluminum. 6061-T6 aluminum is precipitation-hardened 6061 aluminum. 6061 aluminum is one of the most versatile, common aluminum alloys that may be heat treated. The main alloying elements for 6061 aluminum are silicon and magnesium.

sfm range for 6061 aluminum

To guarantee safe lifting operations of metal and wooden boards, doors, furniture, sheets, and more, our Vacuum Lifters feature a vacuum pump, filter system, supply hose, heavy-duty lift tube and in-built safety features, as well as ergonomic control valve, handles, and range of suction feet.

aluminum 6061 cnc machining|aluminum alloy machinability chart